Maximum Flexibility with an Integrated Supply Chain We have always been committed to offering customers maximum flexibility. In fact, this allows us to meet their needs and always be ready to support them in their projects. But what is the secret to obtaining true flexibility, the one that really generates tangible benefits? There is certainly only one answer to this question: full control and synergy between all phases of the supply chain, from the estimate to the finished

NEWS

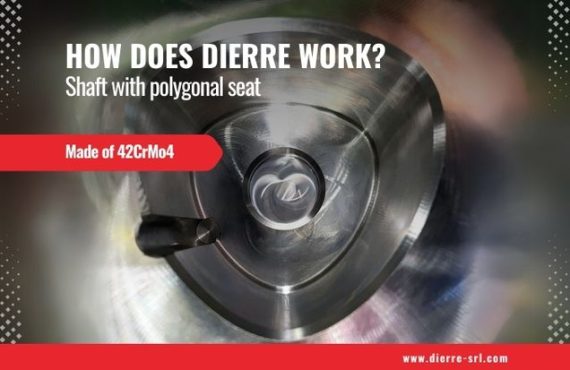

Shaft with polygonal seat How does Dierre work? To involve you in our daily activity, we want to tell you about how we created, with the collaboration of our trusted suppliers for heat treatments, a decidedly special piece. The shaft with a polygonal seat, made of 42CrMo4, encompasses a bit of all the mechanical processes that we perform at Dierre, with the integration of two heat treatments carried out by our trusted suppliers, with

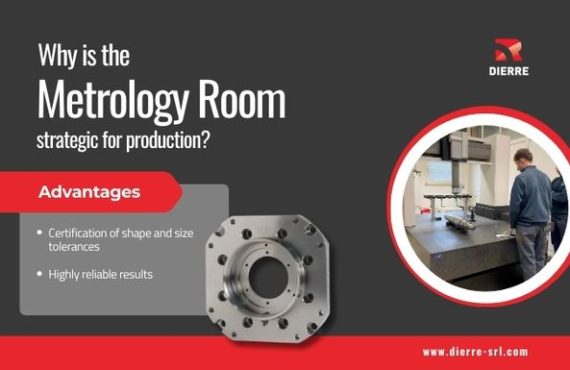

Our metrology room To guarantee our customers excellent results, we constantly invest in innovation and technology. Our metrology room, the strategic heart of production, is a concrete demonstration of this commitment. This specific technical room is an air-conditioned and temperature-controlled environment, equipped with cutting-edge tools and equipment for testing and precision dimensional control. Why an air-conditioned metrology room? Precision is the basis of our quality. Temperature directly affects measurements since, according to the laws

Assembled Groups: Speed and efficiency at the service of our customers Assembled groups? No problem! What are the critical issues for our customers? This is the question we ask ourselves with the aim of constantly improving the services we offer. We are increasingly asked to supply assembled groups, composed of products of our own production and commercial materials: the reduction of delivery times we offer

Dierre soul in a game of ingenuity Talking about your corporate DNA is not easy… but we did it by creating a game of ingenuity that defines us well, both for the materials used and as a solution… Over time, we have produced various institutional materials to talk about our company. But to immediately convey our essence, we thought of an interlocking puzzle that we called HEX. The goal of HEX is to form a hexagon by

Production upon customer request Dierre is not only production and mechanical processing, but it is also the ideal partner for consultancy and technical support for tailor-made creations and unique pieces. To be a true resource for the customer’s production reality it is necessary to provide not only quality, punctuality, technology but also tailor-made responses to all their needs. And this sometimes also means designing and creating unique mechanical elements starting from scratch. Our

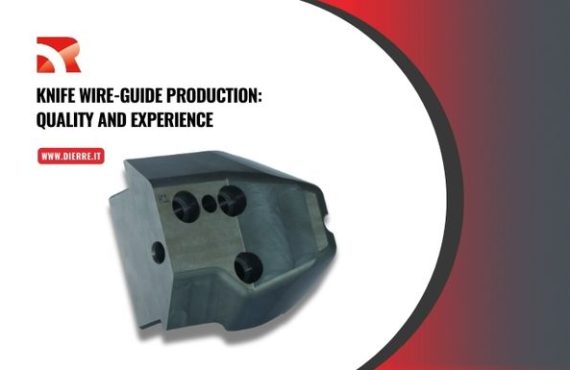

Knife wire-guide production: quality and experience Every single piece we produce is the result of experience, attention to detail and our specific know-how which allow us to resolve any critical issues. The making of the knife wire-guide is one of the highlights of our production. Over the years, we have managed to optimize the production of this part, also by overcoming the numerous critical issues linked to some processes such as boring, rounding, the

Milling: analysis of a complex detail Experience, passion, teamwork: this is our expertise that comes to live into the creation of complex details. Every single element that we put into production is the synthesis of all our experience as well as the teamwork of various specialized professional figures. Today, we want to take you right into the heart of our production, describing the individual steps implemented to create the type of 8-shaped flange that you see in

Loyalty: a fundamental value At Dierre, the concept of loyalty encompasses all aspects of our work: customers, suppliers and even our employees. Loyalty: if you enter this word into a search engine, the results you obtain are mainly limited to the company relationship with its customers and it is often indicated as the result of pre-established rules and strategies, not necessarily shared. For us, loyalty is a bond that arises from the way